I. Introduction to U.S. Regulatory Landscape

A. Importance of Regulatory Compliance

Health care products, including medical devices and dietary supplements, are subject to stringent regulations in the U.S. market to ensure patient safety and product efficacy. For OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) providers, understanding and adhering to these regulations is crucial for market entry and sustained success.

B. Role of the FDA

The U.S. Food and Drug Administration (FDA) is the primary regulatory body overseeing health care products. The FDA’s Center for Devices and Radiological Health (CDRH) regulates the manufacturing, labeling, and distribution of medical devices. Compliance with FDA regulations is mandatory for both domestic and foreign manufacturers seeking to market their products in the U.S.

II. Key Regulatory Requirements for Health Care Product OEM/ODM

A. Establishment Registration and Device Listing

Manufacturers must register their facilities with the FDA annually and list all devices they intend to market in the U.S. This process helps the FDA track manufacturers and ensure compliance with regulatory standards.

B. Premarket Notification and Approval

Most medical devices require Premarket Notification (510(k)), demonstrating substantial equivalence to a legally marketed device. Higher-risk devices may need Premarket Approval (PMA), which involves submitting clinical data to prove safety and efficacy.

C. Quality System Regulation (QSR)

The QSR (21 CFR Part 820) outlines requirements for designing, manufacturing, packaging, labeling, and storing medical devices. Manufacturers must implement a robust quality management system (QMS) to ensure consistent product quality and safety.

D. Medical Device Reporting (MDR)

Manufacturers are required to report incidents where their devices may have caused or contributed to death or serious injury, as well as certain malfunctions. This helps the FDA monitor device performance and take corrective actions when necessary.

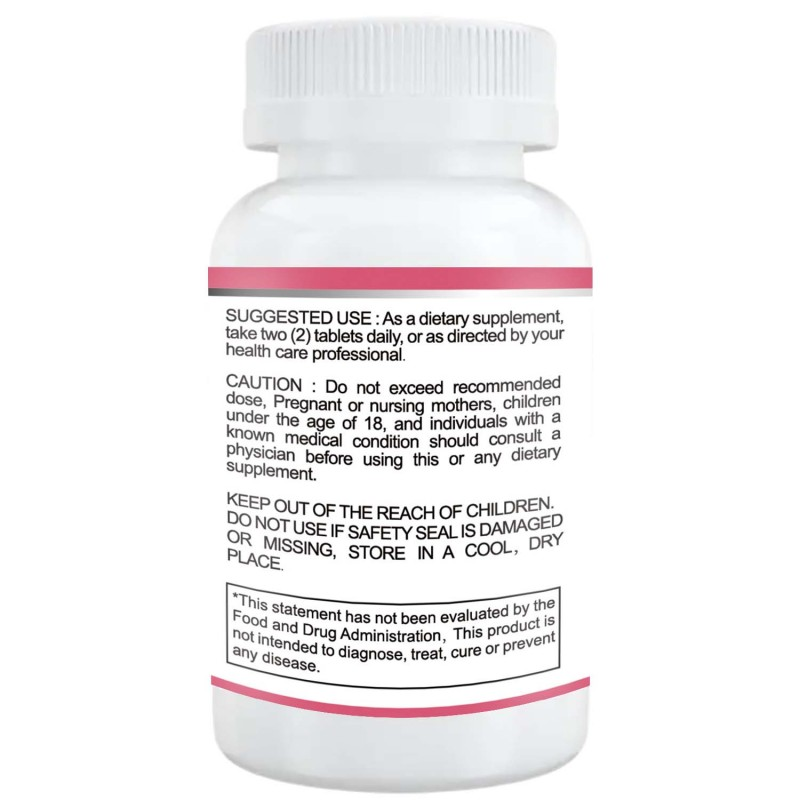

E. Labeling and Packaging

Labeling must be accurate and informative, including all necessary warnings and instructions for use. Packaging should protect the device’s integrity and comply with any specific regulatory requirements.

III. Strategies for Ensuring Regulatory Compliance

A. Partnering with Experienced Manufacturers

Selecting an experienced OEM/ODM partner with a proven track record of FDA compliance can mitigate risks and streamline the regulatory process. Such partners often have established quality systems and are familiar with U.S. regulatory requirements.

B. Implementing Robust Quality Management Systems

Investing in a comprehensive QMS ensures that manufacturing processes meet FDA standards. This includes design controls, process validation, and corrective and preventive actions (CAPA).

C. Staying Informed and Adaptable

Regulations can change, and manufacturers must stay updated on the latest FDA guidelines. Engaging with regulatory consultants or leveraging FDA resources like “Device Advice” can help navigate updates.

D. Navigating the Approval Process

Understanding the 510(k) and PMA processes is essential. Manufacturers should prepare thorough submissions, including clinical data and design validations, to expedite approvals.

E. Conclusion

Regulatory compliance is a cornerstone of health care product manufacturing in the U.S. market. By understanding and adhering to FDA regulations, partnering with experienced manufacturers, implementing robust quality systems, and staying informed, OEMs and ODMs can successfully navigate the regulatory landscape and bring safe, effective products to market.